Les métaux non ferreux et leurs utilisations

L'un des premiers métaux non ferreux découverts par l'homme est le cuivre, ce qui a marqué le début de l'âge du cuivre. De plus, afin d'utiliser au maximum ce métal, l'homme a dû apprendre l'art du forgeage et du moulage. Le bas point de fusion et la facilité de fabrication ont fait du cuivre le métal de prédilection de l'homme.

L'âge du bronze a rapidement suivi l'âge du cuivre lorsque les humains ont découvert qu'ils pouvaient allier le cuivre à l'étain pour produire du bronze. Les humains utilisent les métaux non ferreux depuis plus longtemps que leurs homologues ferreux. En fait, vers 5000 avant JC, les humains ont développé une technique utilisée pour fabriquer le bronze. Cette technique impliquait la fusion et l'alliage du cuivre avec d'autres métaux comme l'étain et l'arsenic. Le début de cette fusion et la période d'alliage ont mis fin à l'âge de pierre, marquant le début de l'âge du bronze.

Les autres métaux non ferreux découverts sont l'or et l'argent. Ces métaux ont remplacé le bois et la pierre comme ornements humains. Cependant, comme ces métaux sont rares, ils sont utilisés pour fabriquer des articles de luxe.

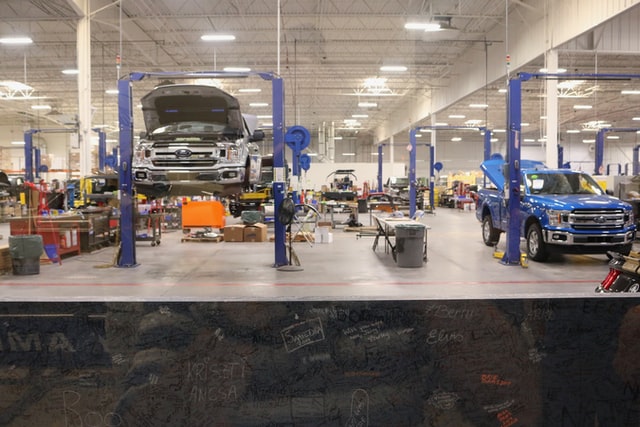

Aujourd'hui, nous utilisons des métaux non ferreux pour fabriquer des outils, des moteurs de véhicules, des pipelines, des couverts, des câbles électriques, des ornements et bien d'autres.

Tous les métaux non ferreux partagent certaines propriétés. Examinons ces propriétés.

Haute résistance à la corrosion et à la rouille : Les métaux non ferreux n'ont pas une teneur importante en fer, ce qui les rend très résistants à la rouille et à la corrosion. Cela les rend idéales pour la fabrication de gouttières, de toits et d'autres applications qui nécessitent une exposition aux éléments.

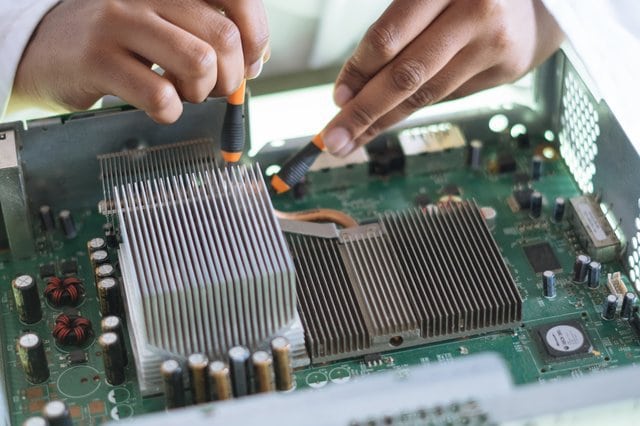

Non magnétique : Ce type de métal est non magnétique, ce qui les rend idéaux pour les câblages et l'électronique.

Prix: Si vous souhaitez utiliser des métaux non ferreux pour la fabrication, sachez qu'ils sont plus chers que leurs homologues ferreux. Il y a deux raisons principales qui le rendent coûteux. Le premier est la demande et l'offre de ces métaux. La demande de métaux non ferreux est supérieure à leur offre, ce qui les rend assez coûteux à acquérir. L'autre raison est qu'ils ont des applications dans diverses industries, allant de l'automobile et de l'aérospatiale à l'ingénierie et à la construction. Cela signifie que de nombreuses industries recherchent ces métaux dont l'offre est limitée, ce qui les rend plus chers.

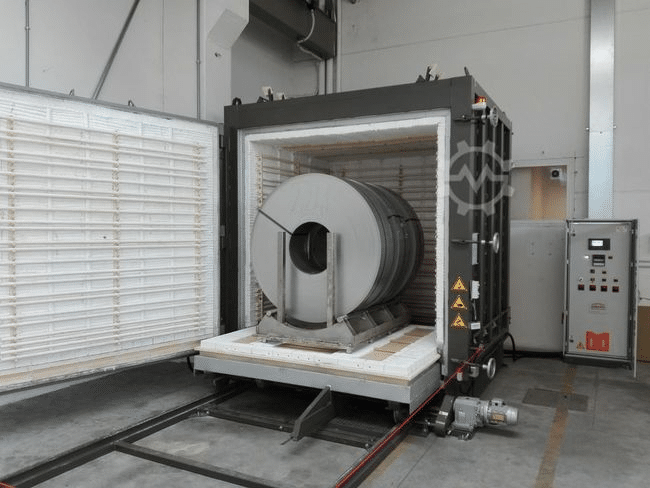

Recyclabilité: Tous les types de métaux sont recyclables. Les métaux non ferreux peuvent être recyclés individuellement avec un risque de dégradation minimal par rapport aux métaux ferreux. Ils conservent également leurs propriétés chimiques au cours du processus. Il est important de recycler ces métaux car ils ne sont pas facilement disponibles. Une autre raison de recycler est que le processus réduit les déchets et protège l'environnement. Pour ce faire, il économise de l'énergie lors de l'extraction à partir de sources naturelles et diminue les émissions de gaz qui se produiraient pendant le processus d'extraction.

INVENTAIRE DES METAUX NON-FERREUX

- Les métaux précieux comme l’argent, le platine et l’or

- Le cuivre et ses alliages comme le bronze et le laiton

- Le Nickel, le Palladium et le Platine

- Le Titane

- L’Aluminium

- L’Étain et le Plomb

- Le Zinc

Avec un tel éventail de matériaux dans ce groupe, beaucoup de propriétés mécaniques recommandant le fer peuvent être découvertes dans les métaux non ferreux. Par exemple, des alliages d’aluminium ou de titane pourraient remplacer l’acier dans de nombreuses occasions, si le prix n’était pas aussi élevé. Les capacités magnétiques du fer pourraient être imitées avec du nickel, du cobalt ou des éléments de terres rares alliés à d’autres métaux.

Toutefois, parce que les métaux non ferreux coûtent souvent plus cher, ils ont tendance à être choisis pour leurs attributs uniques (résistance à la corrosion, conductibilité électrique et thermique, légèreté, amagnétique..) par rapport à l’acier. Certains métaux sont très recherchés étant donné leur rareté: avant que la fabrication de l’aluminium ne soit largement répandue, l’aluminium était un métal de luxe utilisé dans la vaisselle haut de gamme.

Il existe trois métaux de coulée non ferreux remarquables.

Le cuivre et ses alliages

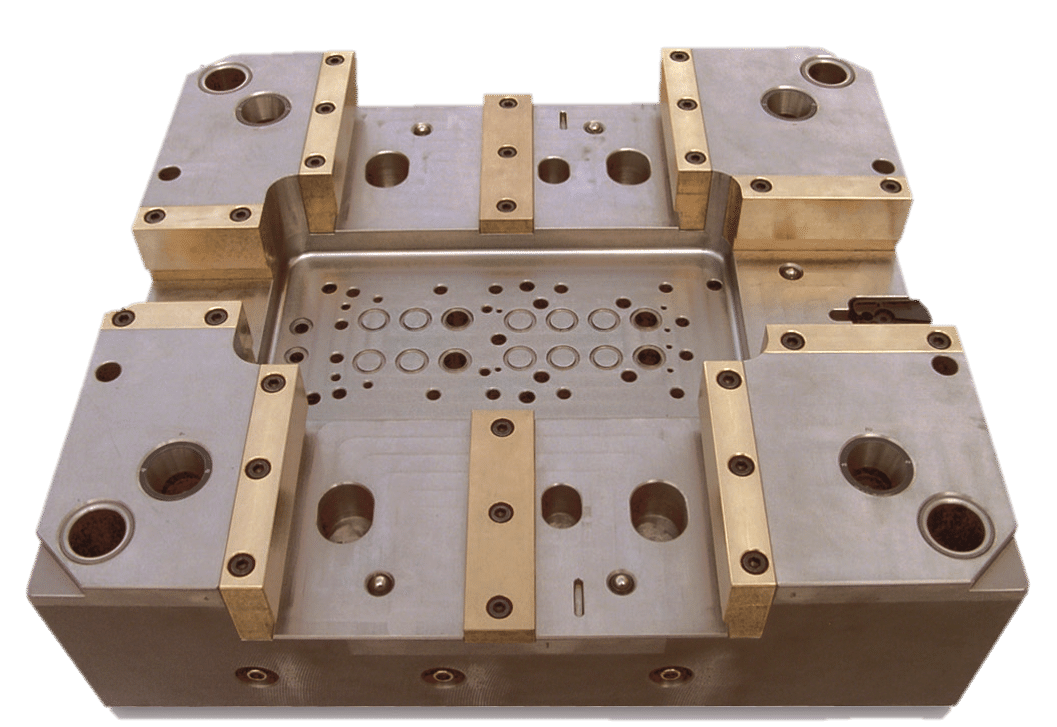

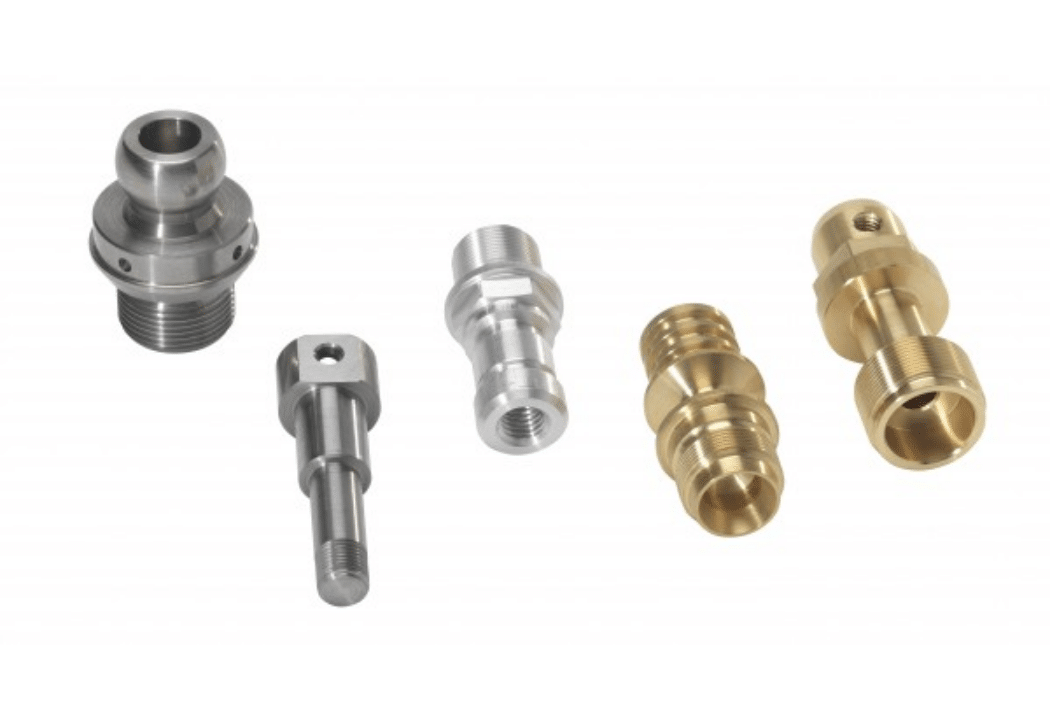

Le cuivre et ses alliages, le laiton (cuivre et zinc) et le bronze (cuivre et étain), ont des usages divers dans plusieurs industries. Cela est dû à ses propriétés de conductivité électrique élevée, de ductilité, de conductivité thermique et de résistance à la corrosion. Lorsqu'il n'est pas allié, il est mou et ductile.

Ces propriétés rendent le cuivre et ses alliages bons pour la fabrication de récipients de chauffage et d'échangeurs de chaleur. Sa conductivité électrique élevée le rend idéal pour les moteurs et le câblage. De plus, le cuivre a des applications dans la production de raccords de plomberie, de matériaux de toiture, de statues et d'ustensiles de cuisine.

En revanche, le cuivre est assez cher et les fils fabriqués avec ce matériau sont généralement sensibles à la corrosion. Il perd également sa forme car le matériau est doux.

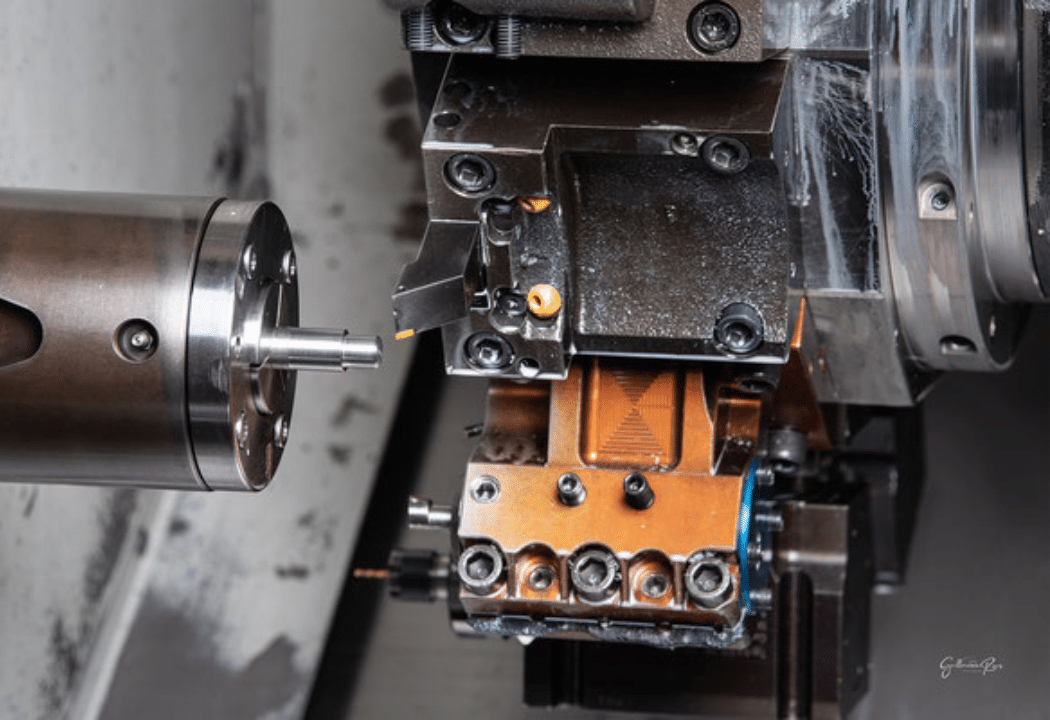

Le bronze et le laiton ont été les premiers métaux coulés par l’humanité à l’Âge de Bronze et ces alliages de cuivre sont encore coulés au sable de nos jours. Ils sont fondus à des températures beaucoup moins élevées que les matériaux ferreux et ils moulent bien les détails, de sorte qu’ils sont souvent utilisés dans des applications décoratives comme la statuaire. Le bronze et le laiton sont plus doux que l’acier mais restent tout de même résistants à la corrosion même en présence de sel, de sorte que ces métaux sont utilisés dans des applications marines standards comme les raccords sur les bateaux. Le laiton est également résistant aux « irritants», qui sont l’usure du métal contre lui-même. Pour cette raison, le laiton est parfois moulé pour les pièces mécaniques, comme les hélices marines, ou usiné pour les roulements à billes et les fermetures éclair. Les deux alliages sont assez dispendieux car ils dépendent du cuivre, un métal également en demande pour ses propriétés électriques.

Le nickel

Le nickel est un autre métal non ferreux courant. Les propriétés de ce métal argenté comprennent la résistance à la corrosion, la ténacité et la tolérance à la température. Bien que ce métal existe sous une forme pure, cette forme a des applications minimes.

Cependant, ce métal acquiert d'excellentes propriétés mécaniques et chimiques lorsqu'il est allié à d'autres éléments. Cela lui donne une application dans la section chaude des avions, des automobiles et des équipements marins, ainsi que dans la production d'équipements cryogéniques.

De plus, le nickel peut résister à la corrosion même à des températures élevées, ce qui en fait un bon matériau pour produire des clous, des tuyaux et des blindages.

Le titane

Ce métal a un excellent rapport résistance/densité ainsi qu'une résistance à la corrosion. Un alliage de ce métal avec de l'aluminium et du fer crée un métal léger mais solide.

Sans mélange, titane est comparable à certains aciers, bien qu'il soit moins dense. Ce métal a des applications dans plusieurs industries, notamment l'industrie agricole, médicale, sportive, militaire, aérospatiale et automobile.

Le plomb est un mauvais conducteur d'électricité, mais il est ductile, dense et malléable. Lorsqu'il est exposé à l'air, le plomb change de couleur. Il a également des applications dans la production de gaines de câbles, de verre au plomb et de ceintures de poids pour la plongée. Ses principales utilisations dans le monde d'aujourd'hui sont dans la production de réservoirs d'acide, de câbles électriques et de batteries. Cependant, le plomb est chimiquement inerte. Cela signifie qu'il ne réagit pas avec de nombreux produits chimiques.

L’argent

L'argent est un métal relativement mou avec un aspect lustré et brillant. C'est un métal avec la meilleure conductivité thermique et électrique, hautement malléable et résistant à la corrosion.

L'argent est utilisé dans de nombreuses industries, de la technologie solaire et de l'électronique au brasage et au soudage. Les autres applications de l'argent comprennent les roulements de moteur, la monnaie, la purification de l'eau, la vaisselle, la médecine et les bijoux. En revanche, il a la plus faible résistance de contact de tous les métaux.