| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| Alloy C-22 | NICKEL ALLOY | UNS N06022 / 2.4602 | 8,61 | 800 | 400 |

| Alloy 75 | NICKEL ALLOY | UNS N06075 / 2.4630 | 8,37 | 790 | 380 |

| Alloy 80A | NICKEL ALLOY | UNS N07080 / 2.4631 | 8,19 | Svt état | Svt état |

| Alloy 90 | NICKEL ALLOY | UNS N07090 / 2.4632 | 8,18 | 1175 | 752 |

| Alloy 200/201 | NICKEL ALLOY | UNS N02200 / 2.4066 | 8,89 | 462 | 148 |

| Alloy 263 | NICKEL ALLOY | UNS N07263 / 2.4650 | 8,36 | 1004 | 585 |

| Alloy C-276 | NICKEL ALLOY | UNS N10276 / 2.4819 | 8,89 | 760 | 350 |

| Alloy A-286 | NICKEL ALLOY | UNS S66286 / 1.4980 | 7,94 | 1020 | 690 |

| Alloy 330 | NICKEL ALLOY | UNS N08330 / 1.4864 | 8,08 | 552 | 207 |

| Alloy 400 | NICKEL ALLOY | UNS N04400 / 2.4360 | 8,84 | 550 | 240 |

| Alloy K-500 | NICKEL ALLOY | UNS N05500 / 2.4375 | 8,44 | 620 | 280 |

| Alloy 600 | NICKEL ALLOY | UNS N06600 / 2.4816 | 8,47 | 655 | 310 |

| Alloy 601 | NICKEL ALLOY | UNS N06601 / 2.4851 | 8,11 | 738 | 338 |

| Alloy 625 | NICKEL ALLOY | UNS N06625 / 2.4856 | 8,5 | 827 | 414 |

| Alloy 686 | NICKEL ALLOY | UNS N06686 / 2.4606 | 8,73 | 722 | 364 |

| Alloy 718 | NICKEL ALLOY | UNS N07718 / 2.4668 | 8,19 | Svt état | Svt état |

| Alloy X-750 | NICKEL ALLOY | UNS N07750 / 2.4669 | 8,28 | Svt état | Svt état |

| Alloy 800 | NICKEL ALLOY | UNS N08800 / 1.4876 | 7,98 | 580 | 290 |

| Alloy 825 | NICKEL ALLOY | UNS N08825 / 2.4858 | 8,14 | 690 | 350 |

| Alloy 901 | NICKEL ALLOY | UNS N09901 / 2.4662 | 8,14 | Svt état | Svt état |

| Alloy 925 | NICKEL ALLOY | UNS N09925 | 8,08 | Svt état | Svt état |

| Alloy DS | NICKEL ALLOY | 1.4862 | 7,86 | 687 | 363 |

| Alloy X | NICKEL ALLOY | UNS N06002 / 2.4665 | 8,2 | 810 | 390 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| CuNi10Fe1Mn | Cupronickel | UNS C70600 / 2.0872 | 8,9 | 280 | 90 |

| CuNi30Mn1Fe | Cupronickel | UNS C71500 / 2.0882 | 8,9 | 340 | 120 |

| CuNi14Al3 | Cupronickel | 2.1504 / UN14A2 | 8,5 | 780 | 590 |

| CuNi12Zn24 | Cupronickel | UNS C75700 / 2.0730 | 8,6 | 360 | 230 |

| CuNi18Zn20 | Cupronickel | UNS C75200 / 2.0740 | 8,7 | 380 | 250 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| Invar 36 | NICKEL IRON ALLOY | UNS K93600 / 1.3912 | 8,11 | 520 | 340 |

| Invar 42 | NICKEL IRON ALLOY | UNS K94100 / 1.3917 | 8,11 | 490 | 250 |

| Kovar | NICKEL IRON ALLOY | UNS K94610 / 1.3981 | 8,2 | 520 | 340 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| CuSn4Zn4Pb4 | BRONZES | UNS C54400 | 8,9 | 450 | 115 |

| CuSn5Zn5Pb5 | BRONZES | 8,8 | 250 | 110 | |

| CuSn7Zn4Pb7 | BRONZES | UNS C93200 | 8,8 | 260 | 120 |

| CuSn6 | BRONZES | UNS C51900 / 2.1020 | 8,8 | 350 | 260 |

| CuSn7Pb15 | BRONZES | UNS C9380 / 2.1183 | 8,8 | 260 | 120 |

| CuSn8-CuSn8P | BRONZES | UNS C52100 / 2.1030 | 8,8 | 450 | 250 |

| CuSn9-CuSn9P | BRONZES | 8,8 | 310 | 270 | |

| CuSn10Pb10 | BRONZES | UNS C93700 / 2.1177 | 9 | 220 | 110 |

| CuSn12-CuSn12P | BRONZES | 2.1052 | 8,8 | 240 | 130 |

| CuSn12Ni2 | BRONZES | UNS C91700 / 2.1060 | 8,9 | 300 | 180 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| CuA1-ETP | COPPER ALLOYS | UNS C11000 / 2.0060 | 8,9 | 300 | 260 |

| CuC1-OF | COPPER ALLOYS | UNS C10200 / 2.0040 | 8,94 | 200 | 80 |

| CuC2-OFE | COPPER ALLOYS | UNS C10100 / 2.0040 | 8,94 | 200 | 80 |

| CuB1-DHP | COPPER ALLOYS | UNS C12200 / 2.0090 | 8,94 | 200 | 40 |

| CuTe | COPPER ALLOYS | UNS C14500 / 2.1546 | 8,9 | 250 | 200 |

| CuAg | COPPER ALLOYS | 8,9 | 250 | 200 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| CuNiSiCr/CuNi2Si | COPPER ALLOYS | UNS C70250 / 2.0855 | 8,9 | 500 | 450 |

| CuNi3Si | COPPER ALLOYS | 2.0857 | 8,8 | 410 | 370 |

| CuCr1Zr | COPPER ALLOYS | UNS C18150 / 2.1293 | 8,9 | 440 | 350 |

| CuCoNiBe | COPPER ALLOYS | UNS C82200 | 8,8 | 680 | 540 |

| CuCo2Be | COPPER ALLOYS | UNS C17500 / 2.1285 | 8,8 | 690 | 570 |

| CuBe2 | COPPER ALLOYS | UNS C17200 / 2.1247 | 8,3 | 1150 | 1000 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| CuAl10Ni5Fe4 | ALUMINUM BRONZE | UNS C63000 / 2.0966 | 7,6 | 680 | 320 |

| CuAl10Ni5Fe5 | ALUMINUM BRONZE | UNS C95500 / 2.0975 | 7,6 | 650 | 280 |

| CuAl9Ni3Fe2 | ALUMINUM BRONZE | 2.0971 | 7,4 | 490 | 180 |

| CuAl11Ni6Fe6 | ALUMINUM BRONZE | 2.0978 | 7,4 | 740 | 420 |

| CuAl10Fe3Mn2 | ALUMINUM BRONZE | 2.0936 | 7,6 | 590 | 330 |

| CuAl13Fe4 | ALUMINUM BRONZE | Hors norme | > 560 | > 470 | |

| CuAl13Fe4-F | ALUMINUM BRONZE | Hors norme | > 900 | > 350 | |

| CuAl14Fe5 | ALUMINUM BRONZE | Hors norme | > 630 | > 540 | |

| CuAl14Fe5-F | ALUMINUM BRONZE | Hors norme | > 650 | > 400 | |

| CuAl15Fe5 | ALUMINUM BRONZE | Hors norme | > 680 | > 590 | |

| CuAl15Fe5 | ALUMINUM BRONZE | Hors norme | > 650 | > 400 |

| Grade | Family | Other designations | Density | Rm (MPa) | Rp 0.2 (MPa) |

|---|---|---|---|---|---|

| CuZn25Al5Mn4Fe3 | HIGH RESISTANCE BRASS | UNS C86200 | 7,8 | 750 | 480 |

| CuZn31Si1 (CW708R) | HIGH RESISTANCE BRASS | 2.0490 | 8,4 | 460 | 240 |

| CuZn40Mn2Fe1 (CW723R) | HIGH RESISTANCE BRASS | 2.0572 | 8,3 | 460 | 270 |

| CuZn35Ni3Mn2AlPb (CW710R) | HIGH RESISTANCE BRASS | 2.0540 | 8,3 | 440 | 200 |

| CuZn37Mn3Al2PbSi (CW713R) | HIGH RESISTANCE BRASS | UNS C67420 | 8,1 | 540 | 250 |

| Grade | Family | Bêta transus (°C) | Rm (MPa) |

|---|---|---|---|

| T35 Gr.1 | TITANIUM | 887 | 240 |

| T40 Gr.2 | TITANIUM | 912 | 345 |

| T50 Gr.3 | TITANIUM | 921 | 450 |

| T60 Gr.4 | TITANIUM | 949 | 550 |

| TA6V Gr.5 | TITANIUM | 996 | 895 |

| Grade | Family | Density |

|---|---|---|

| Tungstène pure (W ≥99.95%) | TUNGSTEN | 19.25 |

| W90Cu10 | COPPER-TUNGSTEN | 16.75 |

| W80Cu20 | COPPER-TUNGSTEN | 15.15 |

| W75Cu25 | COPPER-TUNGSTEN | 14.5 |

| W70Cu30 | COPPER-TUNGSTEN | 13.8 |

| W60Cu40 | COPPER-TUNGSTEN | 12.75 |

| W90NiCu | TUNGSTEN ALLOYS | 17.0 |

| W93NiCu | TUNGSTEN ALLOYS | 17.6 |

| W95NiCu | TUNGSTEN ALLOYS | 18.0 |

| W90NiFe | TUNGSTEN ALLOYS | 17.0 |

| W93NiFe | TUNGSTEN ALLOYS | 17.6 |

| W95NiFe | TUNGSTEN ALLOYS | 18.0 |

| W97NiFe | TUNGSTEN ALLOYS | 18,5 |

| WLa1 | TUNGSTEN ALLOYS | |

| WLa1,5 | TUNGSTEN ALLOYS | |

| WLa2 | TUNGSTEN ALLOYS | |

| WRe5 | TUNGSTEN ALLOYS | |

| WRe26 | TUNGSTEN ALLOYS | |

| WLaZr | TUNGSTEN ALLOYS |

| Grade | Family | Density |

|---|---|---|

| Molybdenum pure (Mo ≥99.95%) | MOLYBDENUM | 10,22 |

| TZM (Alliage de Mo) | MOLYBDENUM ALLOYS | 10,16 |

| Mo90Cu10 | COPPER-MOLYBDENUM | 10 |

| Mo85Cu15 | COPPER-MOLYBDENUM | 9,93 |

| Mo80Cu20 | COPPER-MOLYBDENUM | 9,9 |

| Mo70Cu30 | COPPER-MOLYBDENUM | 9,8 |

| Mo60Cu40 | COPPER-MOLYBDENUM | 9,66 |

| Mo50Cu50 | COPPER-MOLYBDENUM | 9,54 |

| MoLa | MOLYBDENUM ALLOYS | |

| MoLa(Recristalized) | MOLYBDENUM ALLOYS | |

| MoW20 | MOLYBDENUM ALLOYS | |

| MoW30 | MOLYBDENUM ALLOYS | |

| MoW40 | MOLYBDENUM ALLOYS | |

| MoZr17 | MOLYBDENUM ALLOYS | |

| MoTa11 | MOLYBDENUM ALLOYS | |

| MoRe5 | MOLYBDENUM ALLOYS | |

| MoRe41 | MOLYBDENUM ALLOYS | |

| MoNb10 | MOLYBDENUM ALLOYS |

| Grade | Family | Density |

|---|---|---|

| Tantalum (Ta) | TANTALUM | 16,6 |

| Niobium (Nb) | NIOBIUM | 8,6 |

| Tantalum Niobium (TaNB) | TANTALUM | 8,6 |

| Hafnium (Hf) | HAFNIUM | 13,3 |

| Vanadium (V) | VANADIUM | 6 |

| Zicornium (Zr) | ZICORNIUM | 6,52 |

| Rhenium (Re) | RHENIUM | 20,8 |

Also discover our materials:

When it comes to choosing a reliable and professional supplier of non-ferrous and special metals, the name Concept Metal stands out among the leaders in the sector. Specializing in the supply of high quality metals, our company is distinguished by its expertise, innovative methods and customer service.

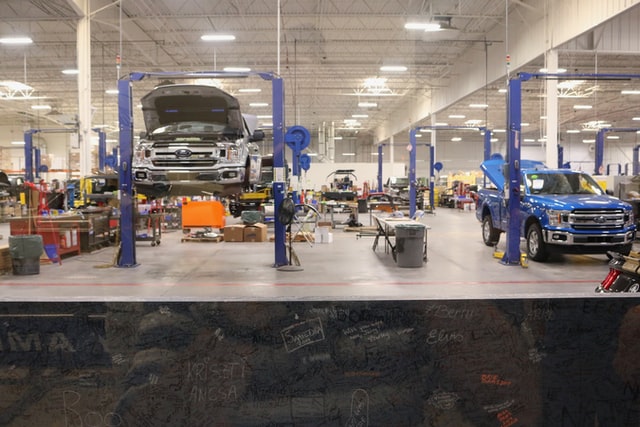

At Concept Metal, customers can find a wide selection of metals, each carefully selected to ensure the best possible quality. The materials on offer include copper, brass, les alliages de nickel and many others. Each metal has specific characteristics adapted to different types of applications, whether they are intended for the automotive industry, space, research, oil, chemistry, aeronautics...

titanium, for example, is prized for its corrosion resistance and durability, making it an ideal choice for demanding environments. Copper is known for its outstanding electrical conductivity, well suited to electronic applications. Each type of metal offered by Concept Metal thus meets specific technical criteria, guaranteeing optimal performance according to the intended use.

One of the first non-ferrous metals discovered by man was copper, which marked the beginning of the copper age. In addition, in order to make the most of this metal, man had to learn the art of forging and casting. The low melting point and ease of manufacture have made copper the metal of choice for man.

The Bronze Age quickly followed the Copper Age when humans discovered that they could combine copper with tin to produce bronze. Humans have been using non-ferrous metals longer than their ferrous counterparts. In fact, around 5000 BC, humans developed a technique used to make bronze. This technique involved melting and alloying copper with other metals such as tin and arsenic. The start of this fusion and the alloy period ended the Stone Age, marking the beginning of the Bronze Age.

Other non-ferrous metals discovered include gold and silver. These metals have replaced wood and stone as human ornaments. However, since these metals are rare, they are used to make luxury goods.

All non-ferrous metals share certain properties. Let’s look at these properties.

High resistance to corrosion and rust: Non-ferrous metals do not have a significant iron content, making them highly resistant to rust and corrosion. This makes them ideal for making gutters, roofs and other applications that require exposure to the elements.

Non-magnetic: This type of metal is non-magnetic, making them ideal for wiring and electronics.

price : If you want to use non-ferrous metals for manufacturing, know that they are more expensive than their ferrous counterparts. There are two main reasons that make it expensive. The first is the demand and supply for these metals. The demand for non-ferrous metals is higher than their supply, making them quite expensive to acquire. The other reason is that they have applications in a variety of industries ranging from automotive and aerospace to engineering and construction. This means that many industries are looking for these metals whose supply is limited, making them more expensive.

recyclability : : All types of metals are recyclable. Non-ferrous metals can be recycled individually with minimal risk of degradation compared to ferrous metals. They also retain their chemical properties during the process. It is important to recycle these metals because they are not readily available. Another reason for recycling is that the process reduces waste and protects the environment. To do this, it saves energy when extracting from natural sources and reduces the gas emissions that would occur during the extraction process.

Read more

- Precious metals such as silver, platinum and gold

- Copper and its alloys such as bronze and brass

- Nickel, Palladium and Platinum

Titanium

- Tantalum

- The Molybdenum

- Tungsten

With such a wide range of materials in this group, many mechanical properties recommending iron can be found in non-ferrous metals. For example, alloys of aluminum or titanium could replace steel in many occasions if the price was not as high. The magnetic capabilities of iron could be imitated with nickel, cobalt or rare earth elements alloyed with other metals.

However, because non-ferrous metals are often more expensive, they tend to be chosen for their unique attributes (corrosion resistance, electrical and thermal conductivity, lightness, non-magnetic) compared to steel. Some metals are highly sought after because of their rarity: before aluminum was widely used, aluminum was a luxury metal used in high-end tableware.

There are three notable non-ferrous casting metals.

Copper and its alloys, brass (copper and zinc) and bronze (copper and tin), have various uses in several industries. This is due to its properties of high electrical conductivity, ductility, thermal conductivity and corrosion resistance. When not alloyed, it is soft and ductile.

These properties make copper and its alloys suitable for the manufacture of heating vessels and heat exchangers. Its high electrical conductivity makes it ideal for motors and wiring. In addition, copper has applications in the production of plumbing fittings, roofing materials, statues and kitchen utensils.

However, copper is quite expensive and the wires made with this material are generally sensitive to corrosion. It also loses its shape, because the material is soft.

Bronze and brass were the first metals cast by mankind in the Bronze Age, and these copper alloys are still cast today. They are melted at much lower temperatures than ferrous materials and they mold the details well. Bronze and brass are softer than steel, but still corrosion resistant even in the presence of salt, so these metals are used in standard marine applications such as boat fittings. Brass is also resistant to “irritants”, which are metal wear against itself. For this reason, brass is sometimes cast for mechanical parts such as marine propellers or machined for ball bearings and zippers. Both alloys are quite expensive because they depend on copper, a metal also in demand for its electrical properties.

Nickel is another common non-ferrous metal. The properties of this silver metal include corrosion resistance, toughness and temperature tolerance. Although this metal exists in a pure form, this form has minimal applications.

However, this metal acquires excellent mechanical and chemical properties when combined with other elements. This gives it an application in the hot section of aircraft, automobiles and marine equipment, as well as in the production of cryogenic equipment.

In addition, nickel can resist corrosion even at high temperatures, making it a good material for producing nails, pipes and shielding.

This metal has an excellent strength/density ratio and corrosion resistance. An alloy of this metal with aluminum and iron creates a light but strong metal.

Unmixed, titanium is comparable to some steels, although it is less dense. This metal has applications in several industries, including the agricultural, medical, sports, military, aerospace and automotive industries.

L'argent est un métal relativement mou avec un aspect lustré et brillant. C'est un métal avec la meilleure conductivité thermique et électrique, hautement malléable et résistant à la corrosion.

L'argent est utilisé dans de nombreuses industries, de la technologie solaire et de l'électronique au brasage et au soudage. Les autres applications de l'argent comprennent les roulements de moteur, la monnaie, la purification de l'eau, la vaisselle, la médecine et les bijoux. En revanche, il a la plus faible résistance de contact de tous les métaux.

One of the strengths of Concept Metal is its impeccable customer service. Its specialists are always available to offer advice and support customers in their choice of materials, according to their needs and constraints. Whether for complex industrial projects or unique creations, their expertise helps determine the most suitable metal and the most efficient processing method.

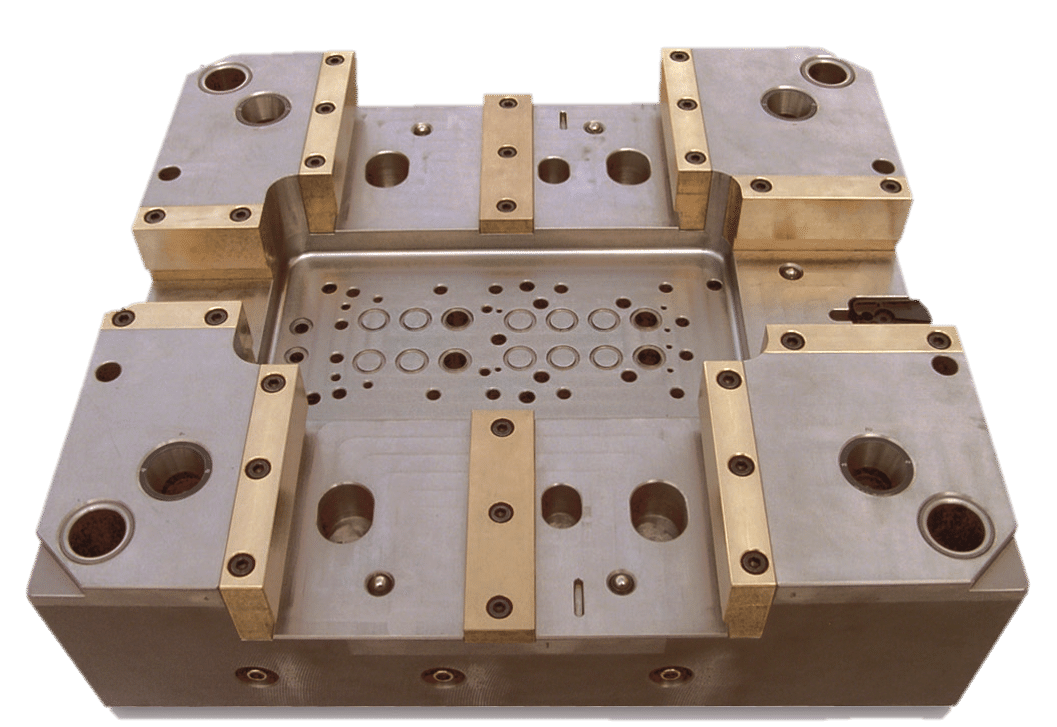

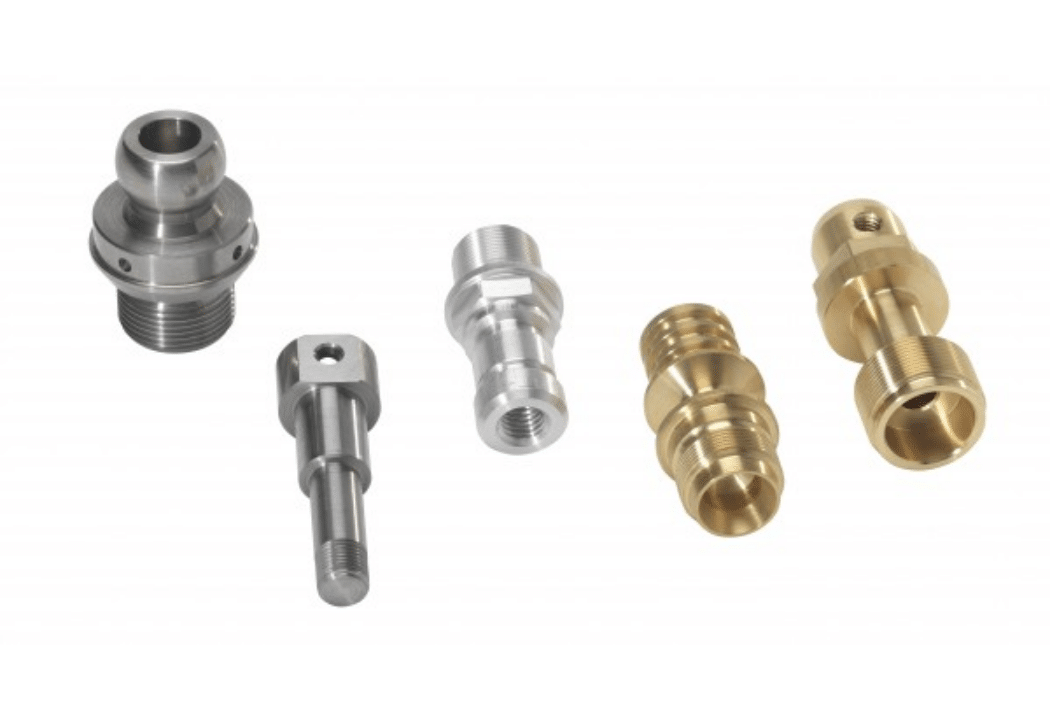

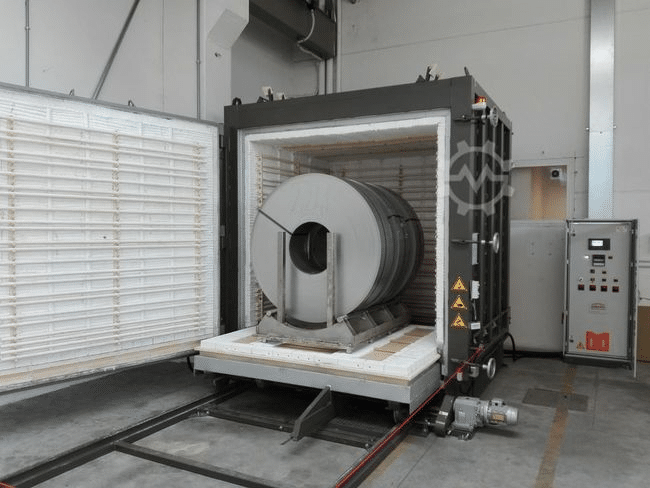

Concept Metal also offers tailor-made solutions, tailored to each specific project. Each part proposed respects the initial plans while ensuring optimal quality. From laser cutting to finishing, through heat treatment and welding, every step is mastered by experienced professionals.

Ensuring quality first of all involves careful selection of materials. Concept Metal works with recognized suppliers, which ensures traceability and consistent quality of raw materials. Each batch of metal is tested to meet the highest standards in order to provide defect-free finished products.

Before shipment, strict quality controls are carried out. These measures ensure not only the satisfaction of the final customer, but also the durability and performance of the products supplied. This attention to detail puts Concept Metal at the top of the industry in terms of reliability and trust.

By choosing Concept Metal, companies benefit from a reliable and competent partner for all their metallurgical projects. Their wide variety of metals, combined with customized services and unwavering rigor, ensures a solution adapted to each specific need. Whether for standard projects or very specific requests, Concept Metal will meet your expectations with professionalism and efficiency.

In short, Concept Metal is much more than just a metal supplier. With its experience, advanced technologies and exemplary customer service, our company offers a consistent and reliable package for all those looking to obtain high quality materials coupled with tailor-made support.