L'une des raisons majeures du choix du tungstène est sa résistance élevée aux températures extrêmes. Ce métal, qui fond à près de 3400 °C, permet d’obtenir un arc électrique stable sans risque de détérioration rapide. Ce point fort évite aussi les contaminations du bain de fusion, ce qui est primordial pour des soudures nettes et durables.

Le soudage TIG (Tungsten Inert Gas) mise justement sur cette stabilité. L’arc formé entre l’électrode non consommable et la pièce métallique reste très précis. Couplée à la protection du gaz inerte, l’utilisation d’une électrode adaptée réduit nettement les défauts tels que les projections ou l’oxydation du joint soudé.

Derrière leur apparence discrète se cachent de multiples atouts. Les électrodes en tungstène permettent de :

La polyvalence de ces électrodes séduira aussi bien les ateliers de maintenance que les industries confrontées à des normes rigoureuses. En conséquence, elles constituent souvent le choix privilégié dès qu’il s’agit d’assurer des soudures fines et fiables.

Si l’industrie mécanique adopte volontiers le procédé TIG, il n’est pas le seul domaine concerné. Le secteur aéronautique compte également sur la précision de ces électrodes pour assembler des composants sensibles requérant une excellente résistance mécanique et aucune inclusion.

L’industrie pharmaceutique et chimique fait appel au soudage TIG lorsque la propreté des joints s’avère indispensable, tandis que le secteur de l’énergie mise sur la robustesse des assemblages produits avec des électrodes de qualité pour garantir sécurité et longévité du matériel.

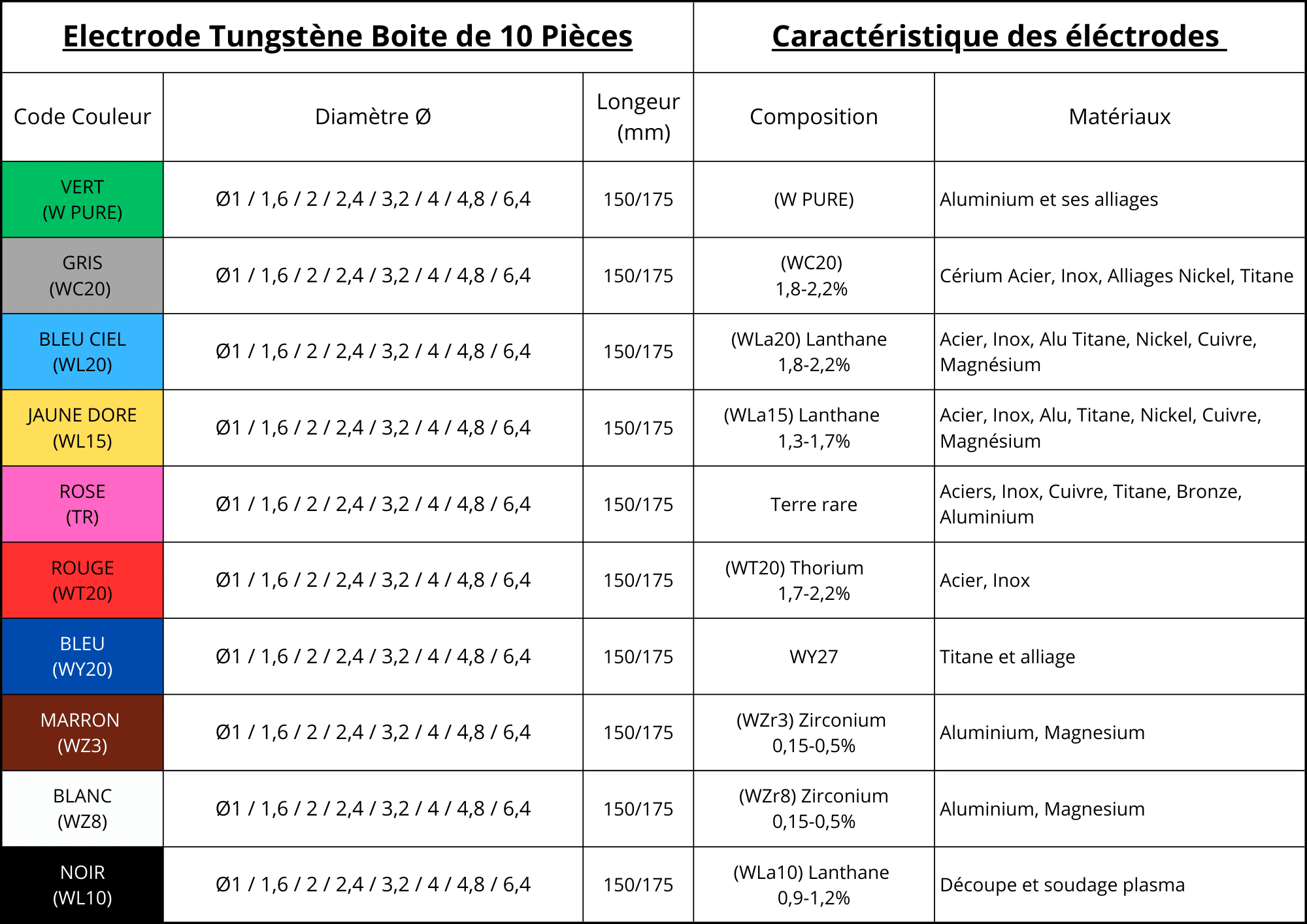

Le choix du type d’électrode ne doit jamais être laissé au hasard. Selon l’application visée et le matériau travaillé, plusieurs qualités peuvent être sélectionnées : chaque nuance apporte son lot d’avantages et s’adapte à des besoins spécifiques dans le processus de soudage à l’arc.

On distingue notamment les variantes pures, cériées, thoriées, lanthanées, mais aussi celles contenant d’autres additifs comme le zirconium ou l’yttrium. Cette diversité répond à des paramètres techniques très précis tels que l’amorçage, la stabilité de l’arc ou la durée de vie de l’électrode.

TIG welding, or Tungsten Inert Gas, is an arc welding process that uses a tungsten refractory electrode. This type of welding is particularly popular for its ability to produce clean and precise welds, thanks to the use of an inert gas that protects the intense heat of the process.

This tool is often preferred for welding non-ferrous metals such as aluminum and certain stainless steel grades. Indeed, this technique is distinguished by its versatility and ability to work with different materials, making complex alloys more accessible.

In the context of TIG welding, the role of inert gas should not be underestimated. Argon is generally used to wrap the electric arc and prevent oxidation of the welded joint. Thus, it guarantees optimal strength and an unimpeachable aesthetic appearance.

By providing a protective atmosphere, the gas allows controlled fusion that limits defects materialized in the form of cracks or inclusions. This control of the process is essential when the current used tolerates little inaccuracies.

Tungsten electrodes are at the heart of the success of TIG welding. Their high heat resistance makes them the perfect tool to withstand extreme temperatures without deteriorating. This material ensures a long service life, thus avoiding frequent stops related to the replacement of electrodes.

Different tungsten grades can be selected according to the project specifications. For example, some alloys allow better arc stability or facilitate low current starting. This tactical choice has a direct influence on the accuracy of the final work.

The robustness of tungsten electrodes gives them an appreciable service life in various industrial applications. Careful maintenance and proper use further extend this longevity, thus optimizing operating costs and increasing the productivity of welding operations.

Demystifying the maintenance of the electrode is then to understand the thermal cycles it supports. Ensuring proper heating management makes possible a continuous evolution of its daily performance.

Choosing a specialized supplier such as Concept Metal for your tungsten electrodes has several advantages. Their extensive expertise in metallurgical resources ensures a reliable and competent partnership, guaranteeing a constant supply of quality materials.

Access to advanced knowledge of welding processes is an undeniable added value of their offer. From the initial selection of materials to their specific application, each step benefits from expert advice aimed at maximizing the efficiency of technical interventions.

Concept Metal offers a wide range of products for all welding configurations. Whether you work with complex non-ferrous metals or different steel grades, they offer targeted solutions to your industrial challenges.